ABOUT US

Splendor-Intl specializes in the research, development, and manufacture of various flame retardant masterbatches.

Being one of the largest flame retardant masterbatch manufacturers in the world, our site occupies 80,000 square meters of land, producing 3,000 tons of masterbatches monthly. And by the end of 2026 the production capacity will triple.

Flame retardants are added to polyolefins, polycarbonate, polyamides, polyester, and other polymers to increase resistance to ignition, reduce flame spread, suppress smoke formation, and prevent polymer from dripping. The primary goal is to delay the ignition and burning of materials, allowing people more time to escape the affected area, limiting property damage as well

Major offerings:

Extruded Polystyrene (XPS) Flame Retardant Masterbatch

Features:High heat resistance , Good smoke-suppression performance, anti corrosion to environment,

Application:Essential component for flame Retardant extruded polystyrene board (XPS).

Brominated antimony flame retardant masterbatch:extensively applied to all different plastic materials,such as ABS、PE、PP、PBT、HIPS、PA.

ISO quality system certified, compliance with RoHS, REACH, and SDS requirements

The factory is located in Yiyang City, Hunan province. It is one hour‘s ride from Changsha Intl. airport,connected with multiple highways.

We strive to be a leading global supplier of flame retardant masterbatches.

We strive to build a more safe and cozy world.

ABOUT US

Splendor-Intl specializes in the research, development, and manufacture of various flame retardant masterbatches.

Being one of the largest flame retardant masterbatch manufacturers in the world, our site occupies 80,000 square meters of land, producing 3,000 tons of masterbatches monthly. And by the end of 2026 the production capacity will triple.

Flame retardants are added to polyolefins, polycarbonate, polyamides, polyester, and other polymers to increase resistance to ignition, reduce flame spread, suppress smoke formation, and prevent polymer from dripping. The primary goal is to delay the ignition and burning of materials, allowing people more time to escape the affected area, limiting property damage as well

Major offerings:

Extruded Polystyrene (XPS) Flame Retardant Masterbatch

Features:High heat resistance , Good smoke-suppression performance, anti corrosion to environment,

Application:Essential component for flame Retardant extruded polystyrene board (XPS).

Brominated antimony flame retardant masterbatch:extensively applied to all different plastic materials,such as ABS、PE、PP、PBT、HIPS、PA.

ISO quality system certified, compliance with RoHS, REACH, and SDS requirements

The factory is located in Yiyang City, Hunan province. It is one hour‘s ride from Changsha Intl. airport,connected with multiple highways.

We strive to be a leading global supplier of flame retardant masterbatches.

We strive to build a more safe and cozy world.

PRODUCTS

Brominated Antimony-Based Flame Retardant Masterbatch

Brominated Flame Retardant Masterbatch is a high-concentration polymer concentrate that blends low-melting brominated flame retardants with antimony trioxide synergist for superior fire performance. It disperses uniformly in thermoplastic resins, achieving UL 94 V-0 at low addition levels while retaining tensile strength and melt flow.

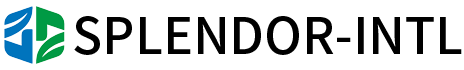

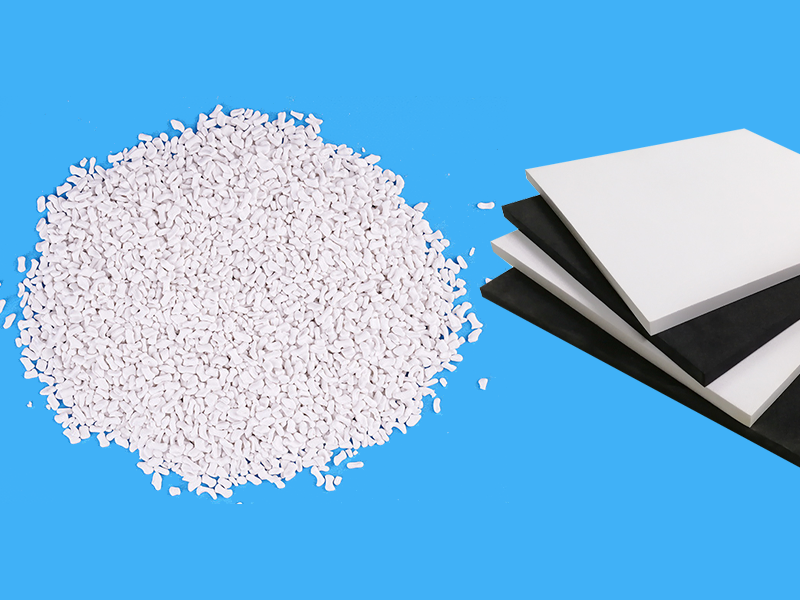

MoreXPS Board Flame Retardant Masterbatch

XPS Board Flame Retardant Masterbatch (a reactive flame retardant masterbatch for extruded polystyrene foam) is a high-efficiency, environmentally friendly additive that offers excellent flame retardancy. It features low addition rates, stable production, good dispersion, and minimal impact on the properties of the base material.

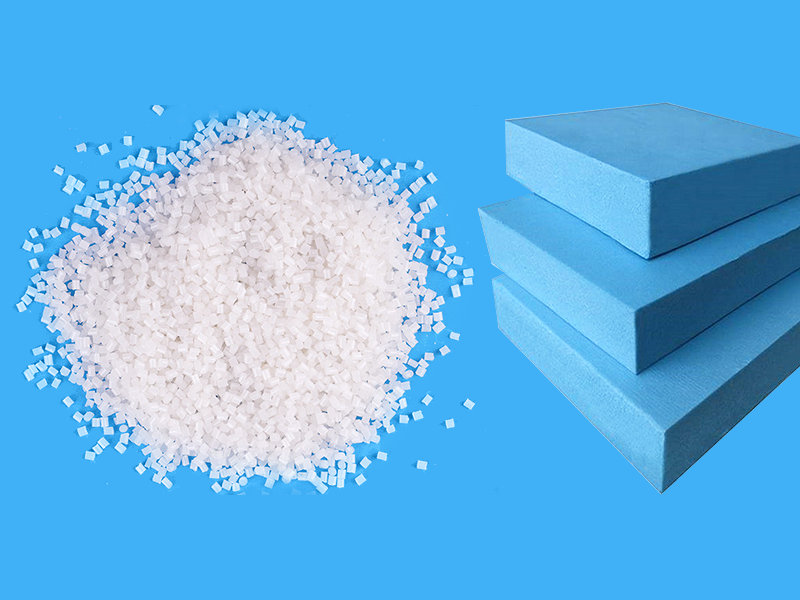

MoreHigh-Efficiency Flame Retardant Masterbatch for Concentrated Grafted PVC

Utilizing internationally advanced flame retardant technology, our product features a carefully formulated blend of highly effective flame retardants and stabilizers. These are integrated uniformly into the PVC substrate through precision processing techniques, forming a homogeneous flame retardant system. Its superior flame-retardant performance enables rapid formation of a dense carbonized layer under extreme conditions, effectively isolating oxygen and heat, significantly reducing fire spread, and ensuring cable safety during fire incidents, thus safeguarding lives and property.

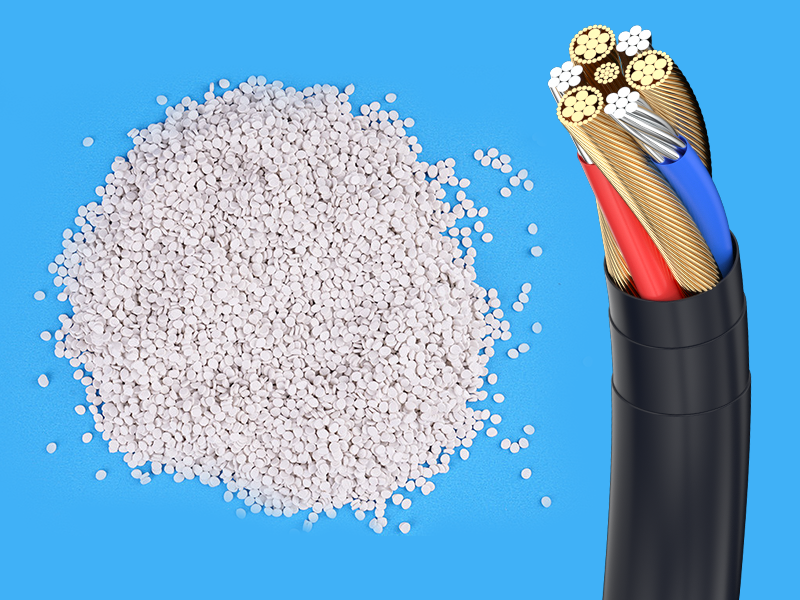

MoreABS Flame Retardant Masterbatch

This flame retardant masterbatch features a high-efficiency composite flame retardant system with excellent compatibility between the flame retardant and resin. It offers strong mechanical properties, good thermal stability, and is suitable for higher processing temperatures and multiple processing cycles. The product is dust-free, provides stable coloration, and can be directly added for injection molding or extrusion pelletizing.

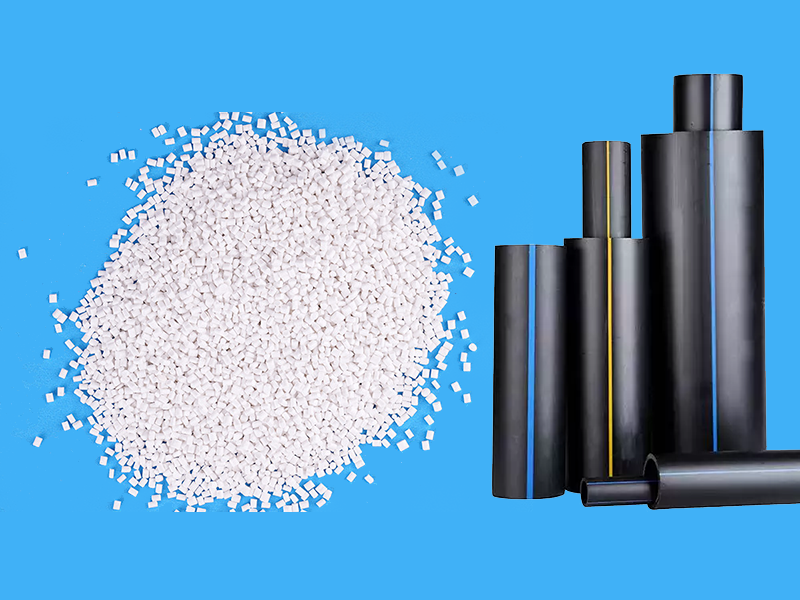

MorePE Flame Retardant Masterbatch

PE Flame Retardant Masterbatch contains fame retardant elements such as antimonytrioxide and is produced by extrusion. It is used for electrical conduits, mining PE pipes, PEsheets, etc. The masterbatch exhibits excellent flame retardancy, dispersion, andcompatibility; it offers good thermal stability and weather resistance; its electrical insulationproperties are outstanding, and its addition effectively enhances the flame retardancy of PE.

MoreLow-Smoke Halogen-Free Cable Material

Under 125°C electron-beam irradiation, the unique properties of low-smoke, halogen-free, flame-retardant polyolefin cable compounds were investigated, focusing on the selection and blending of base materials, compatibilizers, flame-retardant systems, antioxidant systems, and processing aids, as well as their effects on the material’s overall performance. The results showed that using an EVA/HDPE blend system or an EPDM/EVA blend system—together with our self-developed compatibilizer—along with the flame-retardant formulations of Al(OH)_3 / Mg(OH)_2 / Flame Retardant A or Al(OH)_3 / Mg(OH)_2 / Flame Retardant A / Flame Retardant B, plus Antioxidants A and D, successfully produces a halogen-free material with outstanding properties.

MoreEVA Cable Flame Retardant Masterbatch

EVA CableFlame Retardant Masterbatch is a high-efficiency additive designed to enhance the flame retardant properties of EVA-based electric wires. It incorporates various flame retardant additives, including antimony trioxide (Sb₂O₃), into EVA resin, improving processing characteristics, reducing production costs, and enhancing resin compatibility. Special processing techniques ensure effective flame retardancy, minimizing issues such as layer separation, excessive smoke, or surface defects during production. This masterbatch is primarily used to improve the flame retardant performance of EVA electric wires, thereby enhancing the overall safety and quality of the wires.

More产品中心

Products center

APPLICATIONS

At present, both the eco-friendly flame retardant masterbatches and the High-Efficiency Flame Retardant Masterbatch for PVC Wires and Cables have been granted national patents.

MoreNEWS & UPDATES